Plastic injection molding is the process of melting plastic particles (thermosetting/thermoplastic polymers) and, once malleable enough, injecting them under pressure into a mold cavity, filling and curing to produce the final plastic injection moulding products. This technology enables high-volume production of consistent, complex, and dimensionally accurate plastic components. so what is plastic moulding process?

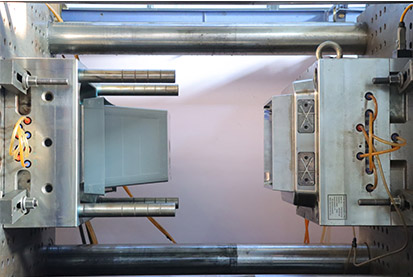

Step 1: Clamping the Mold

The two mold halves are securely clamped together, and resin pellets are fed from the hopper into the barrel, setting the stage for the injection cycle.

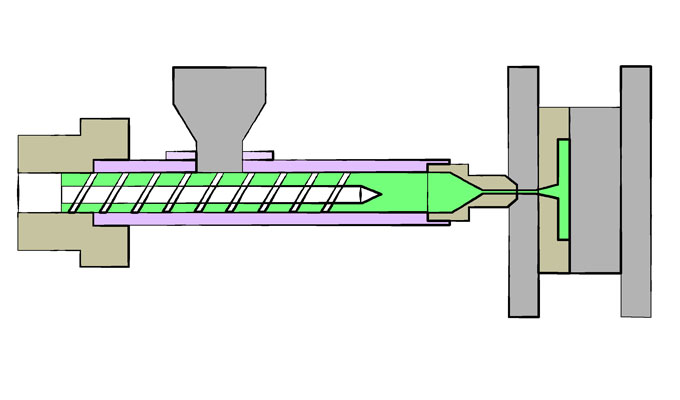

Step 2: Melting and Injection

The screw rotates to convey pellets forward; friction and barrel heaters melt the material, then the screw pushes the melt into the mold cavity at the pressure and speed required to fully fill it.

Step 3: Cooling and Solidification

Once the cavity is filled, the resin needs to cool under controlled conditions so that it solidifies precisely to the mold’s shape and maintains dimensional stability.

Step 4: Screw Retraction

During the cooling phase, the screw retracts and prepares the next shot by drawing in fresh material and beginning to melt it in readiness for the next injection.

Step 5: Ejection of the Part

After the part reaches its ejection temperature, the mold opens and ejector rods or pins push the part out of the cavity—completing one production cycle and preparing for the next.