Plastic molds are tools that are matched with plastic mold making machines in the plastic processing industry to give plastic products a complete configuration and precise dimensions. Due to the wide variety of plastics and processing methods, and the complex and simple structures of plastic injection mold making machines and plastic products, the types and structures of plastic molds are also diverse.

What Is A Plastic Mould Tooling ?

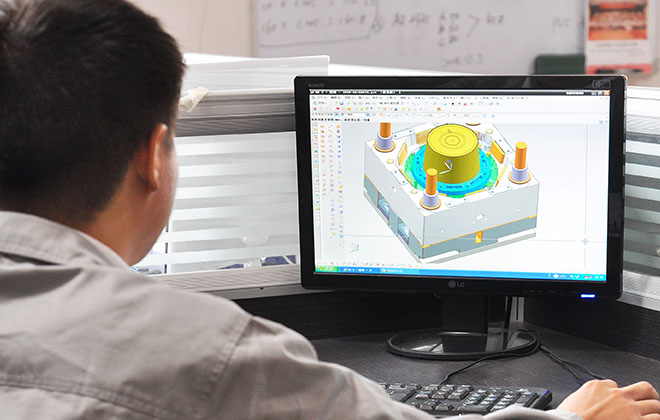

Injection molding tooling is at the heart of plastic injection mold making. Whether it’s a complex operation or simple part, plastic mould tooling – more specifically, tooling design – determines the quality of the injection molding process and the parts produced.

Scientific molding is crucial. It provides largely accurate process of plastic injection mould making that lead to top- quality corridor with constantly tight forbearance and unremarkable confines.

Injection molders and toolmakers experienced in the application and use of scientific molding help clients steer away from arbitrary injection molding tooling design decisions in favor of data-based precision. It sounds elementary, but the factors that could skew injection mould tooling design, engineering, and outcomes are numerous. Engineers specially trained in scientific plastic injection mold making can readily identify and help prevent potential missteps.

Plastic Mould Tooling Capabilities

Plastic injection molds are used when there is a requirement for male or female threads on a plastic component.

An assembly of heated components used to inject molten plastic into the cavities of the injection molding mold.

Includes mechanical action incorporated into the design when a hole, slot, undercut or thread is needed that is not perpendicular to the parting line.

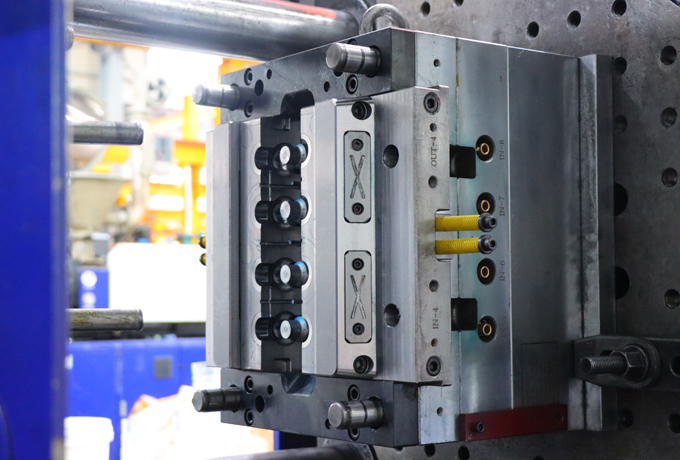

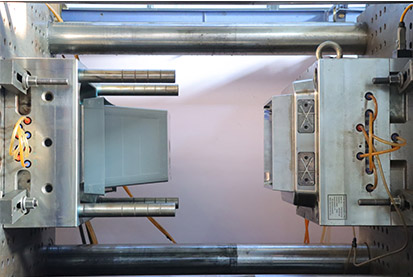

Provides one parting line and the plastic injection moulds splits into two halves; the sprue, runners, gates and cavities are all on the same side.

Plastic Mould Tooling Protection Investment

Preventative:Once a injection molding mould has run a set number of cycles, examinations, conservation and cleaning should be performed. Different types of mold in injection molding age at different rates, so scheduling conservation needs to be proved precisely. Our knowledge and experience gives us the capability to determine the stylish mold conservation schedule specific to each injection moulding mold.

Maintenance:Injection molding tool repairs can be costly. This means it is critically important for injection molds to receive regular maintenance; this is simply the best way to protect your investment and maintain consistent production of quality plastic components. With our on-site plastic injection mould tooling facility we provide quick and efficient mold repairs or revisions.

How To Make Injection Molds?

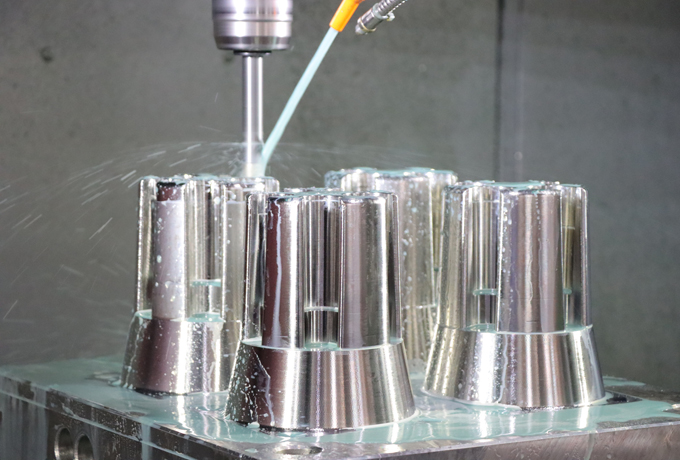

Injection molding is by far the most protean of all injection molding ways. The presses used in this process vary in size and are rated grounded on pressure or heftiness. Larger machines can injection earth auto corridor. Lower machines can produce veritably precise plastic corridor for surgical operations. In addition, there are types of injection moulds that can be used in the plastic molding and manufacturing process, adding its inflexibility for contrivers and masterminds.The process itself is fairly straightforward; still, there are numerous advancements and customization ways that can be used to produce the asked finish and structure. Plastic injection molds, which are generally made from sword, contain depressions that will form the corridor. Melted plastic is fitted into the earth, filling the depressions. The mold is cooled, and the corridor are ejected by legs. Injection moulding raw material list can be varied.

This process is analogous to a jello mold which is filled also cooled to produce the final product.The mold making costs in this system are fairly high; still, the cost per part is veritably provident. Low part cost along with resin and finish options have all contributed to injection molding’s fashionability in moment’s manufacturing geography.