When considering custom injection molding, it's of great importance to assess the complexity level of your project and let that dictate the customization level you need not only from the injection mold toolings themselves, but from front-to-back in working with molders.

Custom injection moulding depends on multiple scientific methods, analytical tools and injection moulding process technology in order to meet the precision and performance requirements for complex plastic components and applications. Although faster time to market is a definite consideration for custom injection molding projects, it isn't pursued at the cost of part design, injection moulding material selection, mold design and injection moulding process control. In order to achieve product design and end-use goal accurately, custom injection molders will use these key product development stages to inform choices about the appropriate injection moulding process step by step such as scientific molding, insert molding, multi-shot molding, overmolding, etc.

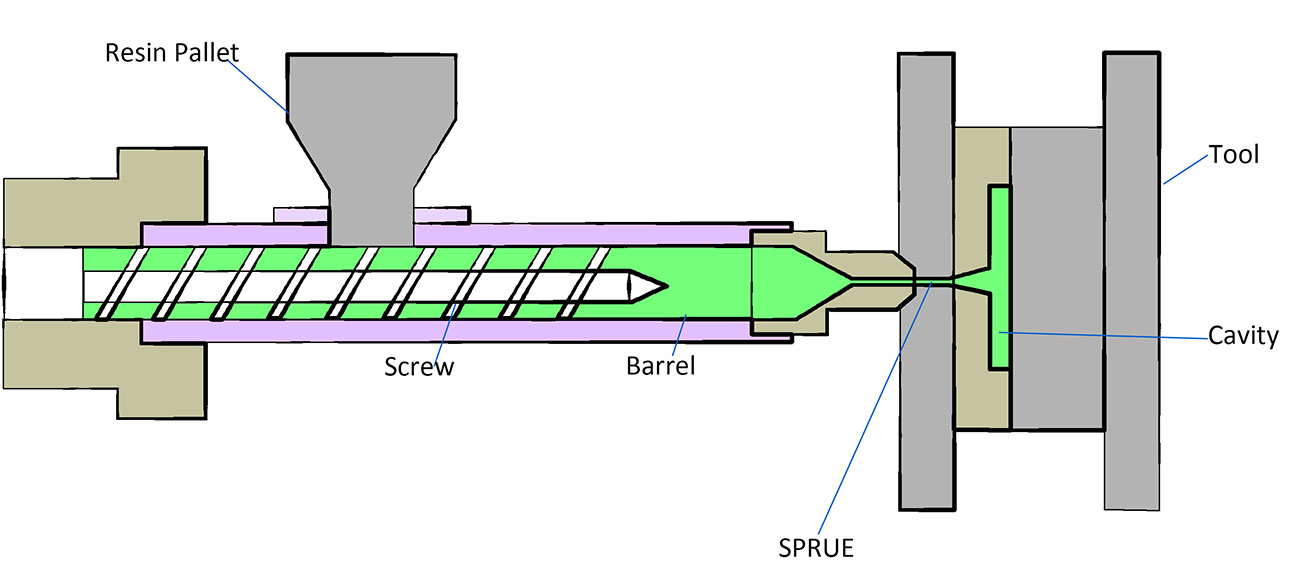

Injection moulding application: Injection molding involves injecting hot, molten plastic material into a mold, which is then cooled and solidified to form the product. Injection moulding method is suitable for the mass production of complex products, especially in the field of plastic processing that occupies a large proportion.

Step 1: The tool closes and resin pellets are fed from a hopper into the barrel, which signifies the start of the injection moulding process steps.

Step 2: The screw rotates to auger the pellets forward toward the tool and resulting friction plus barrel heaters make pellets melt. The screw is pushed forward and injects the material at the force and speed necessary to properly fill the tool cavity.

Step 3: After the tool cavity is filled, the resin must be allowed to cool.

Step 4: When the injection moulding plastic part is cooling within the tool, the screw retracts and reloads with melt in order to prepare for the next injection.

Step 5: As long as the molded material reaches its ideal ejection temperature, the tool opens and the part is pushed out by the forward motion of the ejector rod and pins.

ABS(abs molding): One thermoplastic created by the material of emulsion, with a relatively low melting temperature, and resistant to corrosive chemicals.

Common Application: Enclosures.

Acetal(POM/Delrin): One thermoplastic which is resistant to liquid absorption and chemicals and used to be injection molded.

Common Application: Bearings, bushings, dispensing components.

Acrylic(PMMA): One transparent polymer with excellent tensile, bending strength, less cost and comparable properties to polycarbonate.

Common Application: Clear enclosures, light pipes and LED lights.

As a professional plastic moulding business, Keyplast plastic injection molding company specializes in molding industry for 40 years. We provides one-stop turnkey solution, from product design, prototyping, mould design, injection moulding process step by step, sample confirmation, mass production, packaging, shipping and after-sale service. We help to provide efficient and professional suggestions for our clients, thus bringing their concepts into reality.

Keyplast has a professional R&D and Engineering Team of 13 engineers. Per your 2D/3D drawings and samples, we could make moulds design such as overmold design and then send you for confirmation. If any defects, such as the issue of demoulding issue or sink marks, we will offer professional suggestion to improve your drawings or modify the drawings according to your request.

Once we receive your request for injection molding, our engineers will check the structure and usage of your product and recommend the best plastic material for your project. We have a professional supply chain of plastic materials, which not only provides the plastic injection moulding raw materials of best quality but also the competitive plastic moulding price. It will benifit all the parties in the project, especially our clients.

In current, Keyplast has 9 injection molding machines of different tonnage, ranging from 90ton to 650ton, which can meet the needs of different sizes of products for different clients or different types of injection moulding products for the same client.

Keyplast has strict quality control of injection molding process steps for each project. We have a effecient follow-up team for the sophisticated management of each step, including drilling, deep hole drilling, CNC milling, high speed CNC milling, grinding, boring, lathing, polishing and assembly. Meanwhile, we have complete moulding implement of professional digital management to avoid manual errors.

Once we receive the inquiry from our client, Keyplast, injection molding business, will forward the drawings or samples to our engineers, check the material, structure and quantity, and then offer the quote to our clients within 24 hours. Every two weeks we will send moulds schedule to our clients and keep the moulding progress updated mutually. If any confusion, our service team will send the feedback within 24 hours to avoid any misunderstanding.

TradeMark Wholesale partnered with Keyplast to complete high-volume production and offer one-stop turnkey solutions.

Keyplast specializes in bucket molding process and assists TradeMark Wholesale to complete bucket project, from making drawings for bucket samples, controlling the whole plastic injection molding process, selecting the right plastic material and finishing high-volume production.