Among plastic products, many industrial products and civil products have internal and external thread designs. Solving the problem of thread demolding of plastic parts is the key to the design of such molds. Generally speaking, there are two types of methods to deal with the thread problem of plastic parts: one is the method of forcibly coming out when the plastic parts and resin allow. One is plastic parts with deep threads, high resin strength, and high thread precision requirements, which must be rotated out. The rotary de-threading structure is divided into two types: manual de-threading and automatic de-threading. The production efficiency of manual de-threading is low, but the mold structure is simple, suitable for small batch production, and the automatic de-threading efficiency is high, the quality is stable, and it is suitable for mass production. In the structure of the automatic rotary unthreading mold, the reliability, stability, and practicality of the structure design must be solved. The structure of the motor-driven automatic de-threading mold described below is stable and reliable, and the mold development should pay attention to the following points:

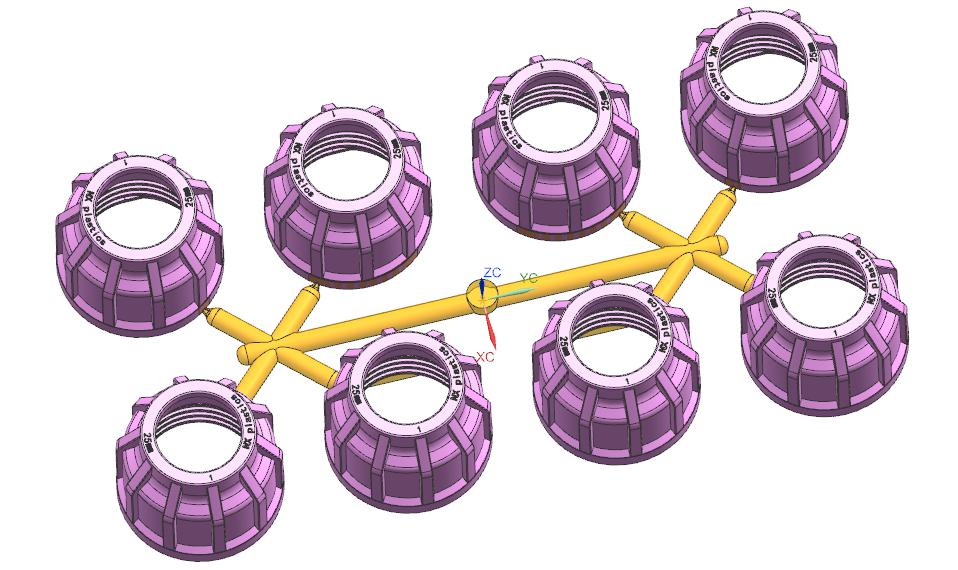

Key Points of Screw Cap Product Design

The screw cap should be reasonably designed and matched with the bottle according to the function of use. Appropriate clearance for later revisions.

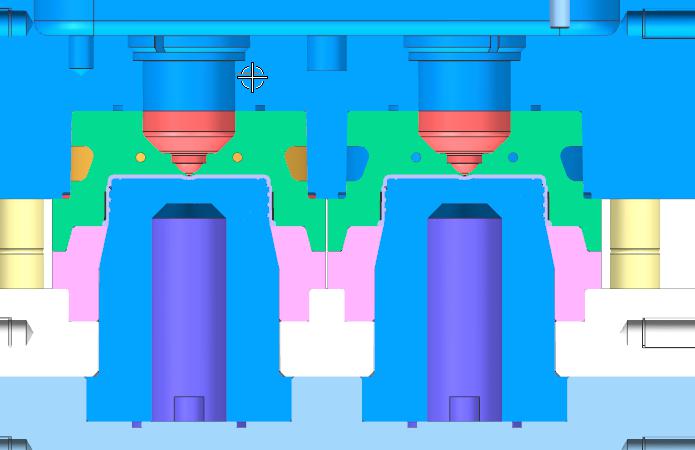

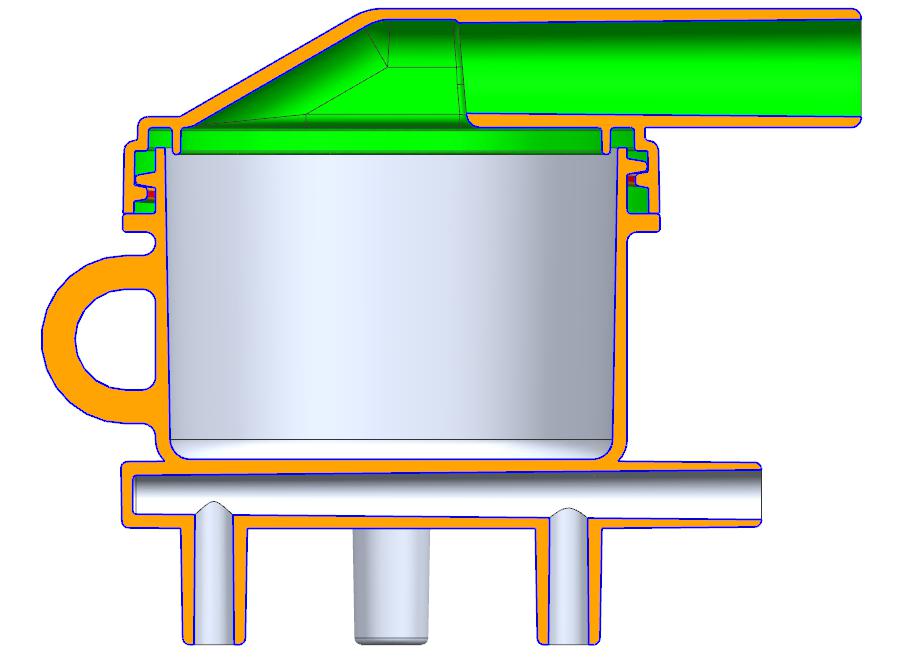

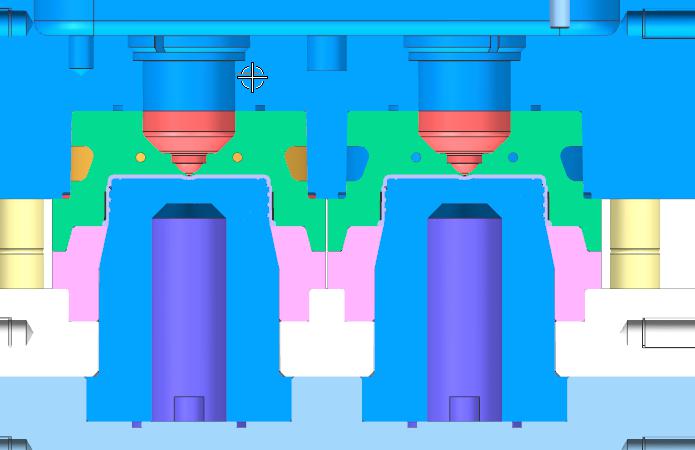

Threaded cap mold gate design

Generally, there are various forms such as side gate pouring and top hot runner pouring.

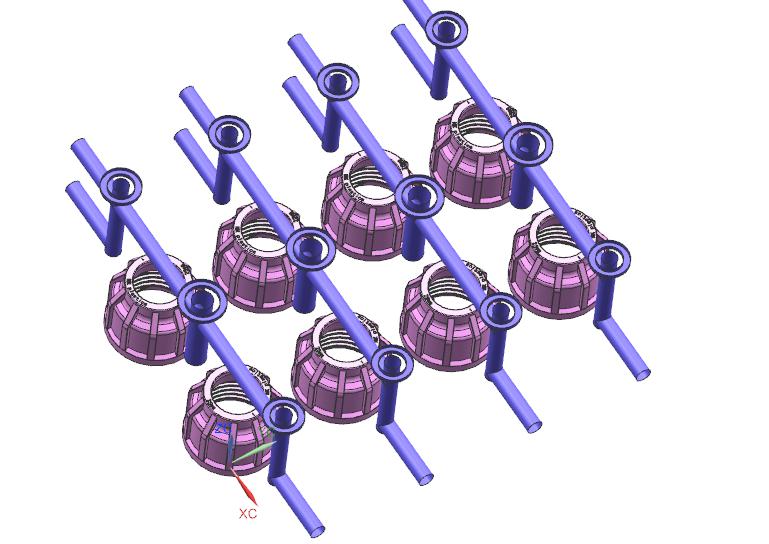

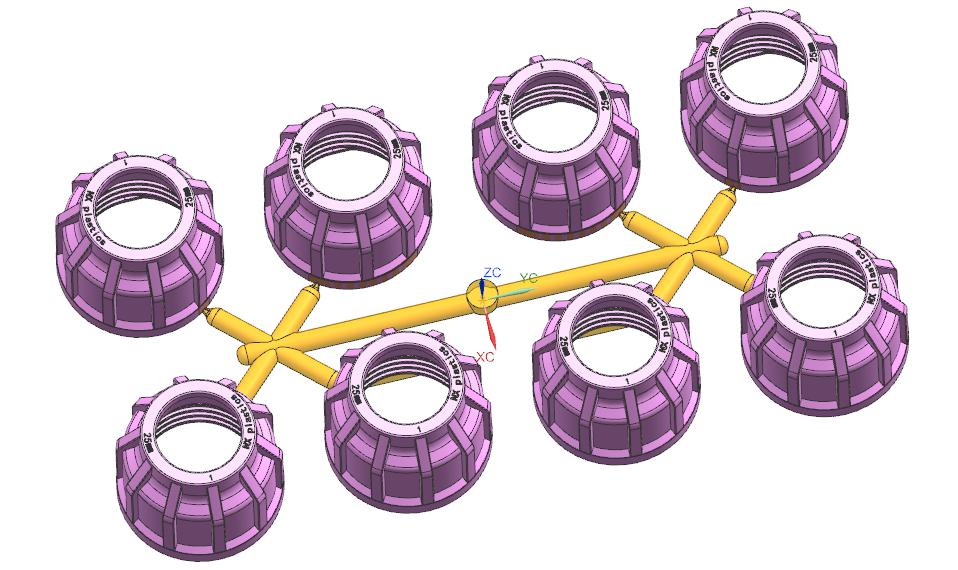

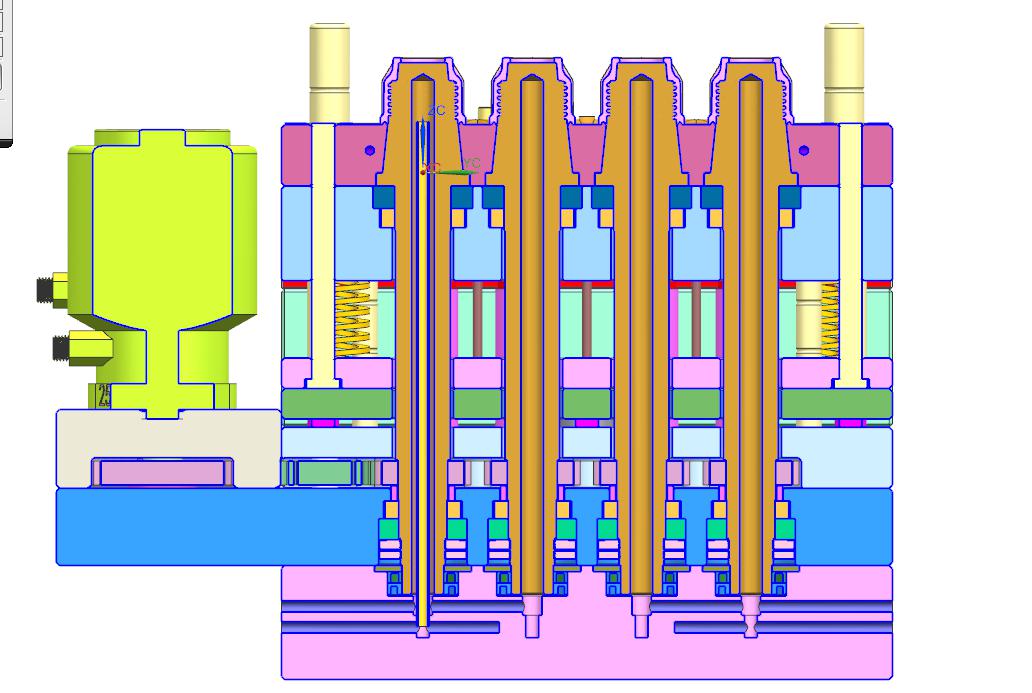

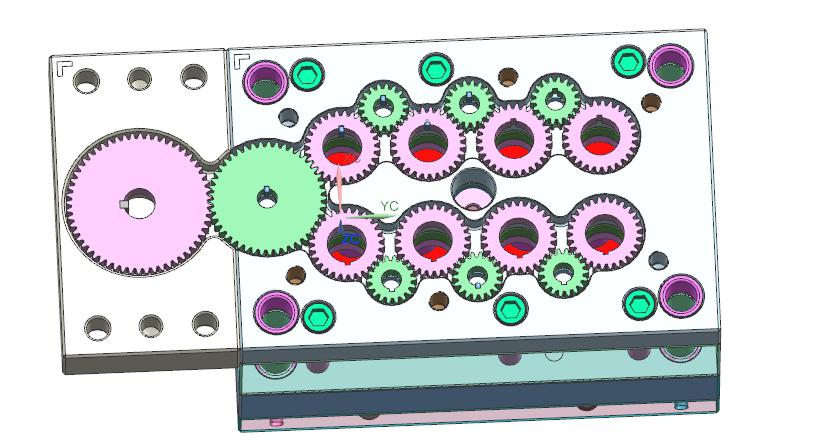

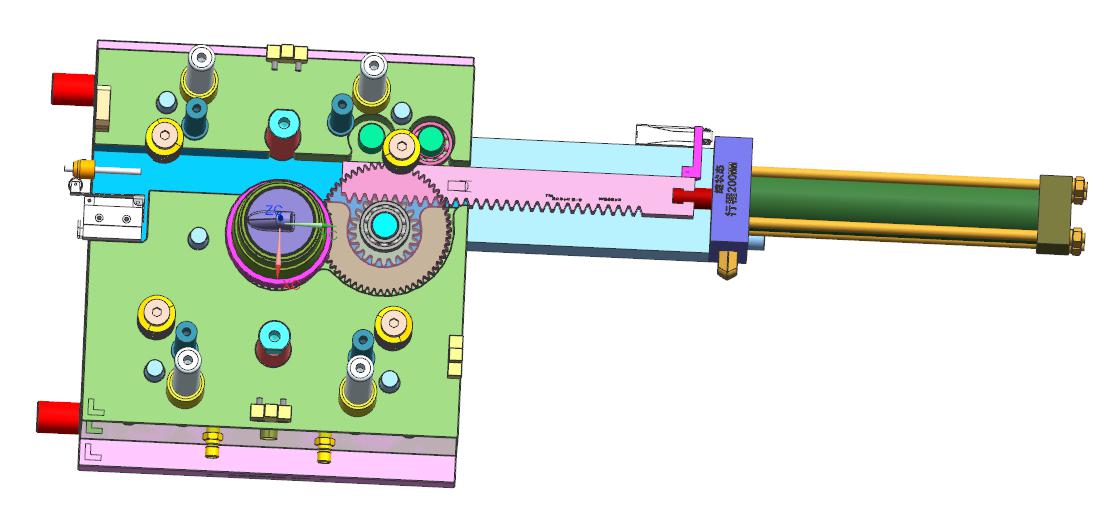

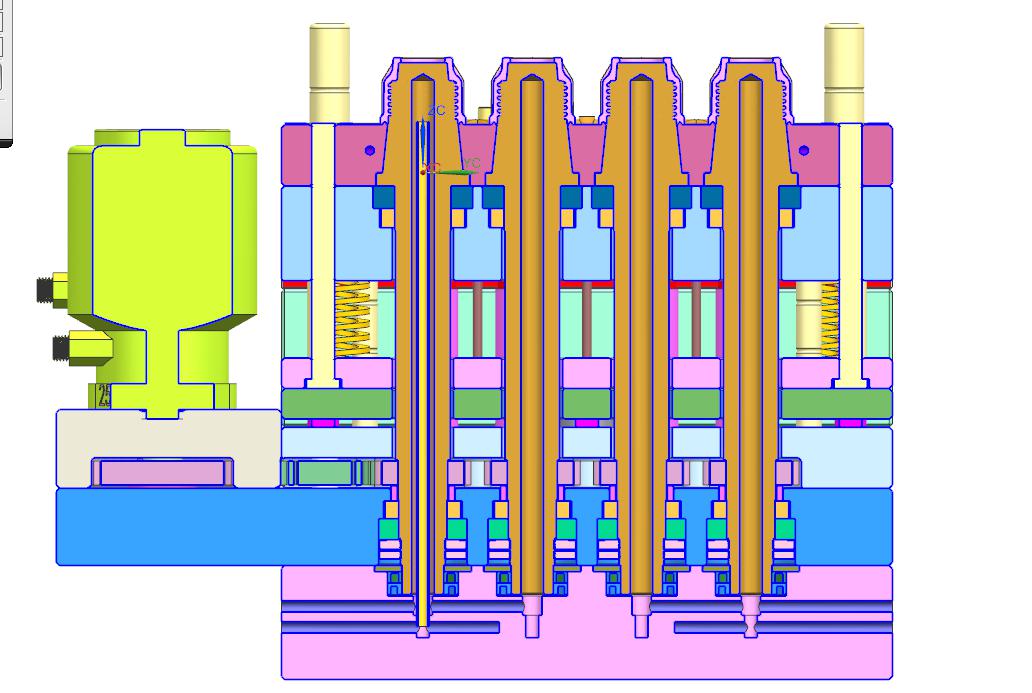

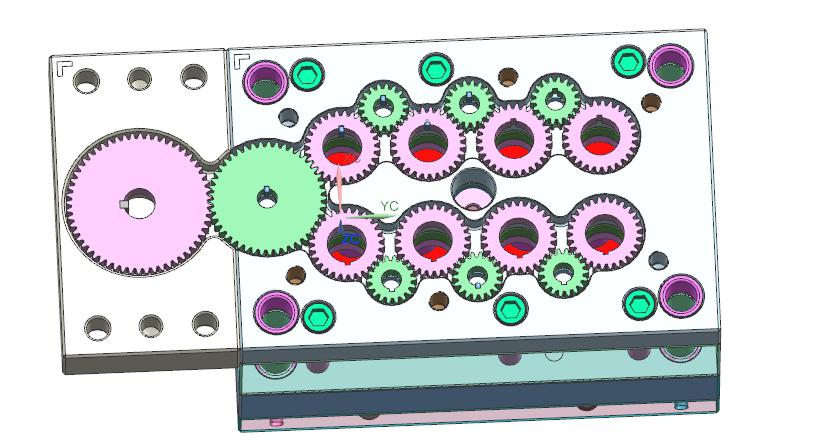

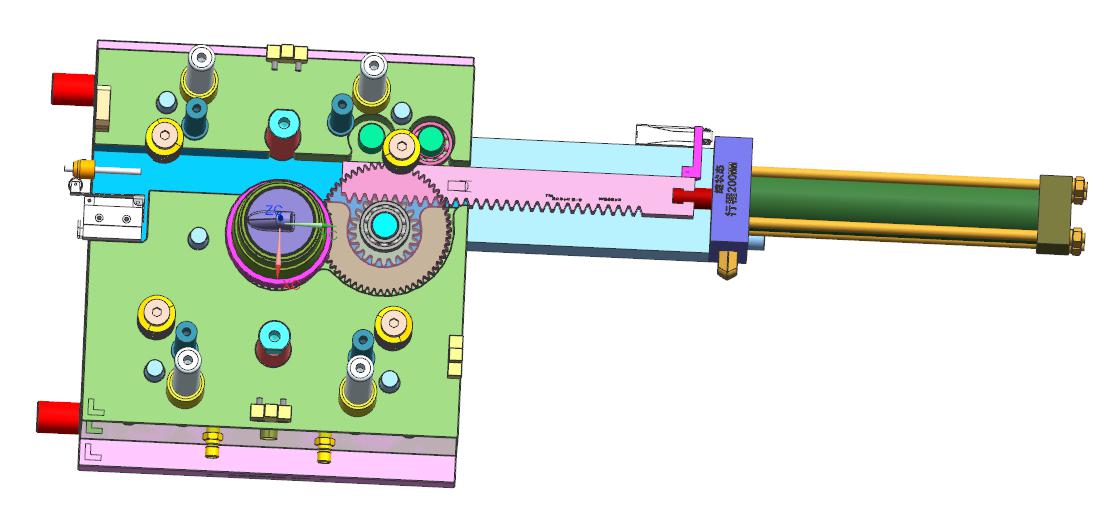

The Motor Rotation and Rack Pull Rotation Release Structure of the Screw Cap Mold

The commonly used screw caps have three structures: push plate forced de-molding, motor rotary de-molding, and rack pulling de-moulding.

1. The push plate is forced to demould, and the structure is simple and suitable for the cover with few thread undercuts.

2. Driven by motor, rotary demoulding

3. The straight rack drives the rotary demoulding

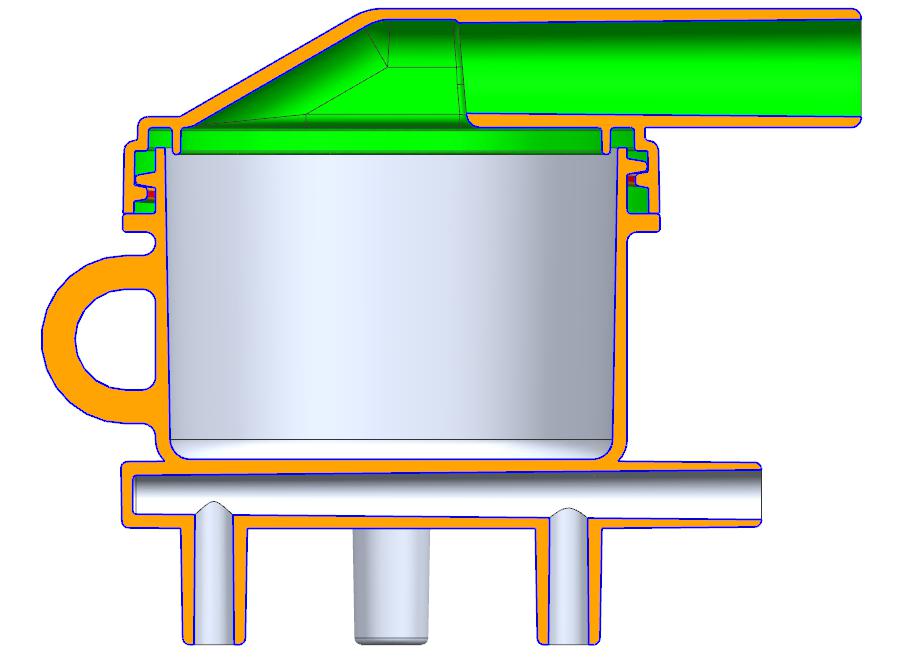

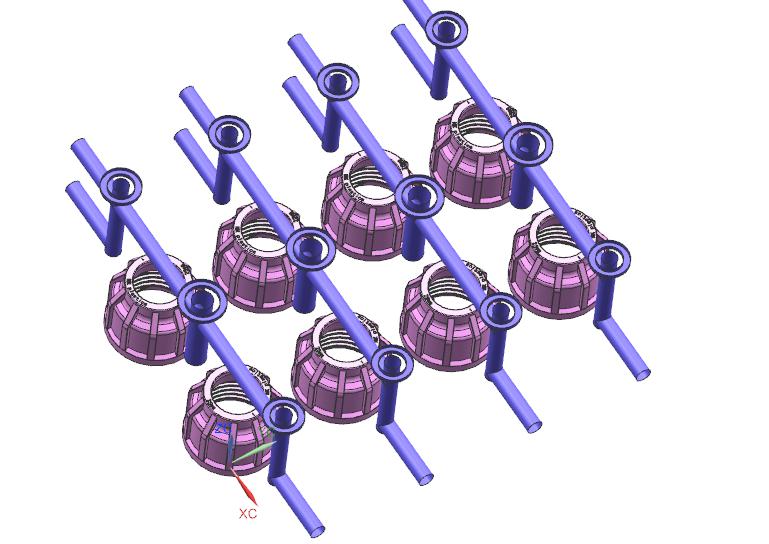

Cooling Design of Screw Cap Mold

The cooling of the screw cap mold is very important. Reasonable cooling can reduce the deformation of the product and shorten the injection cycle. The appropriate size of water channel diameter and uniform distance can ensure uniform cooling of the mold.