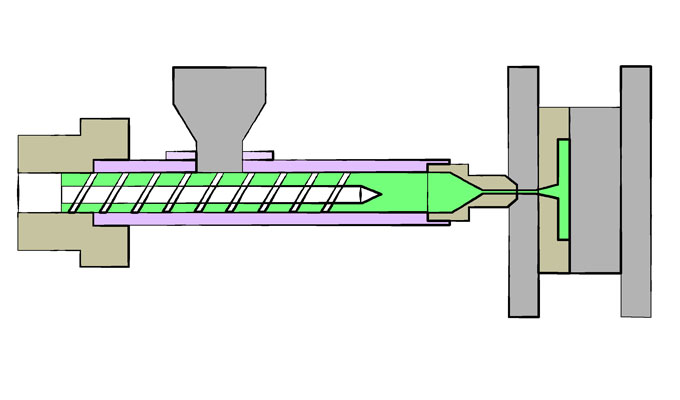

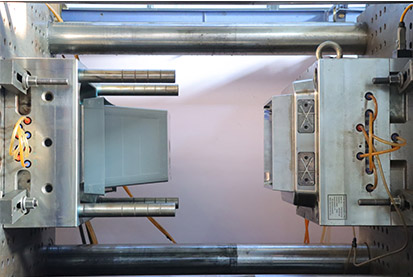

What is plastic injection molding? Plastic Injection molding is a molding method that combines injection and molding. The advantages of plastic injection molding method are fast production speed, high efficiency, operation can be automated, variety of colors, shapes can be from simple to complex, size can be from large to small, and sizes of injection moulding supplies are accurate. The plastic injection moulding product is easy to update, and it can be made into complex shapes. Parts, injection molding/injection moulding is suitable for mass production and plastic molding processing fields such as products with complex shapes.