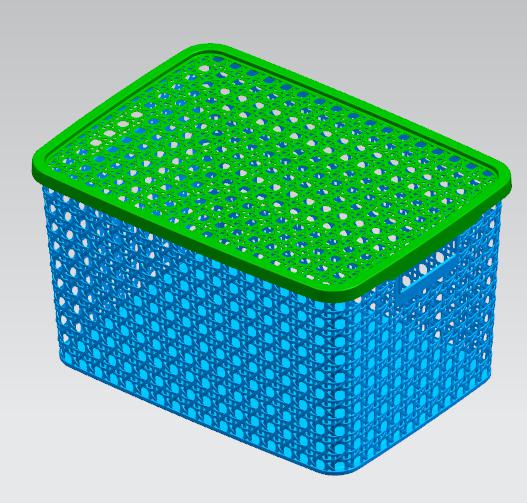

The storage basket is convenient, lightweight and can hold a variety of items. There are a variety of styles, colors, and capacities. It can be used in many occasions without restraint, such as for storing various items at home and office. Items can be better classified and stored, not only saving space but also searching. Daily storage of tidy essentials. Storage basket mold development should pay attention to the following points.

Main Points of Product Design of Storage Basket

The storage basket should be designed according to the function of use and the thickness should be reasonable. It should not only make the product lightweight, but also ensure the strength of use, and the load should not be bent or deformed. The pattern should be designed with reasonable drafting slope and anti-deformation treatment according to the product design.

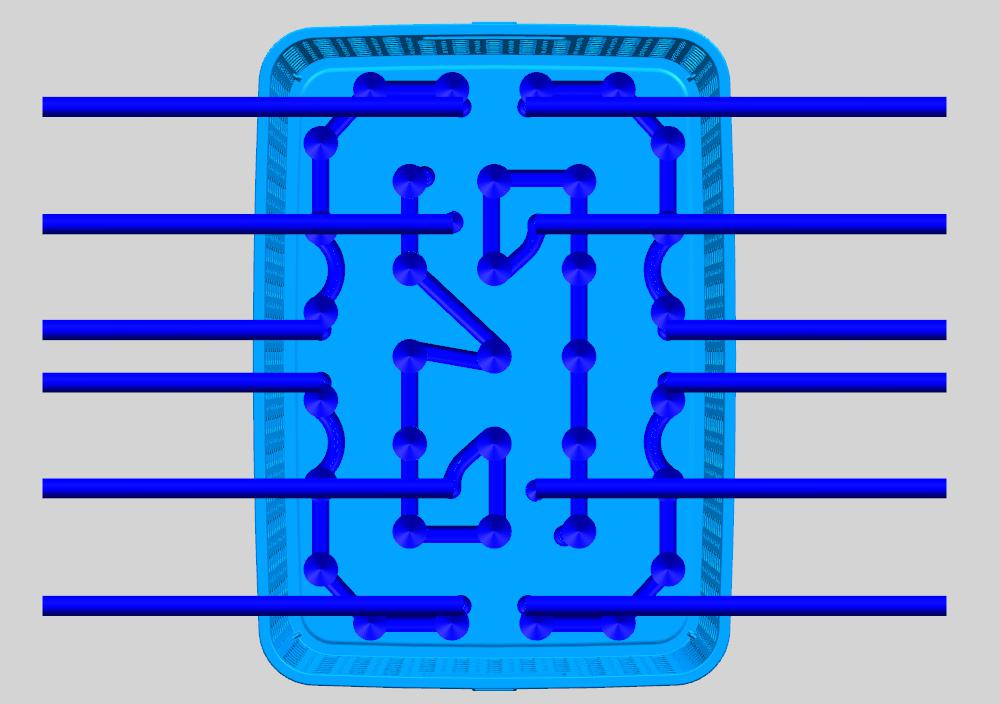

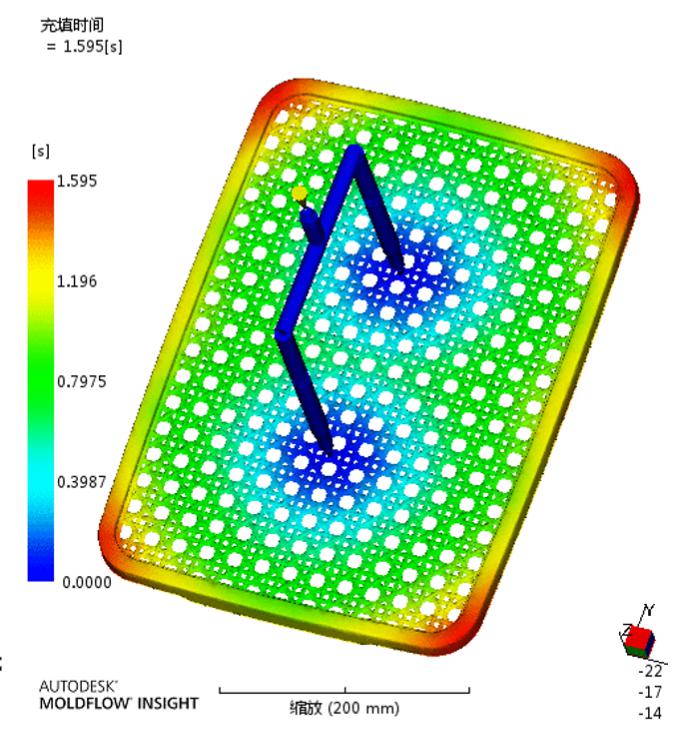

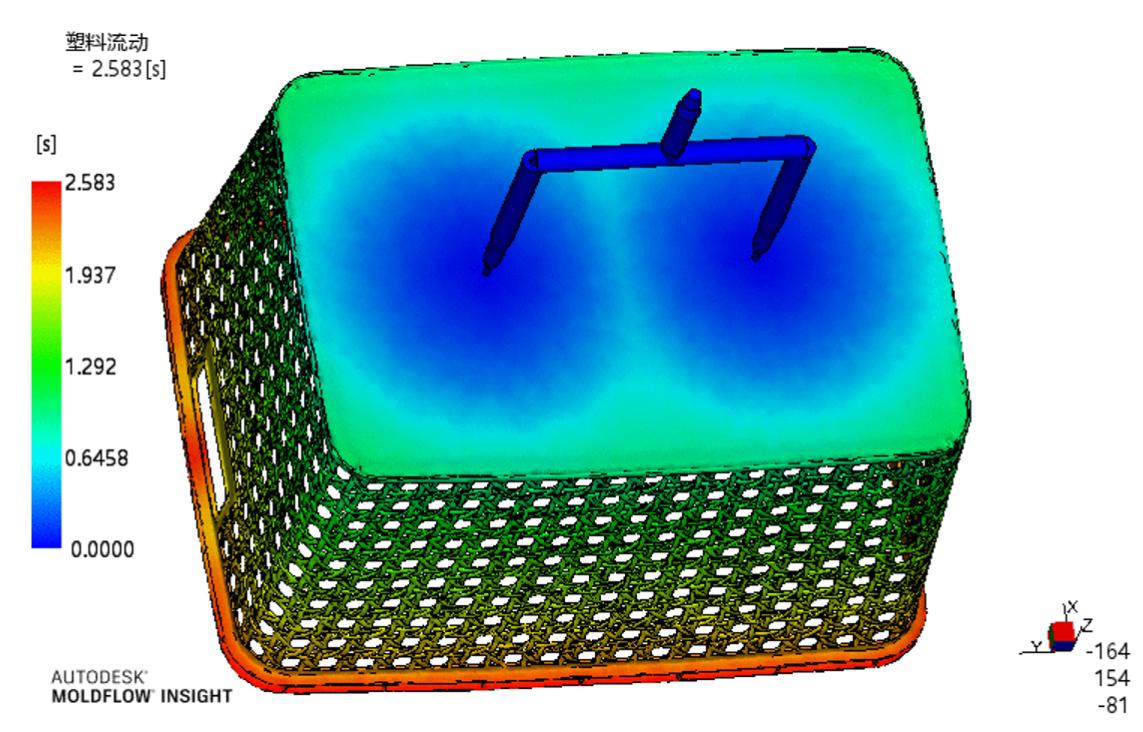

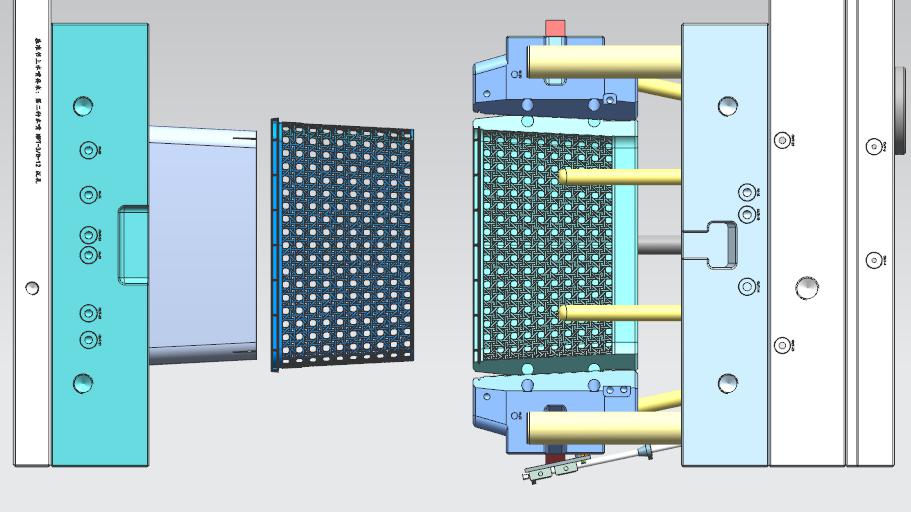

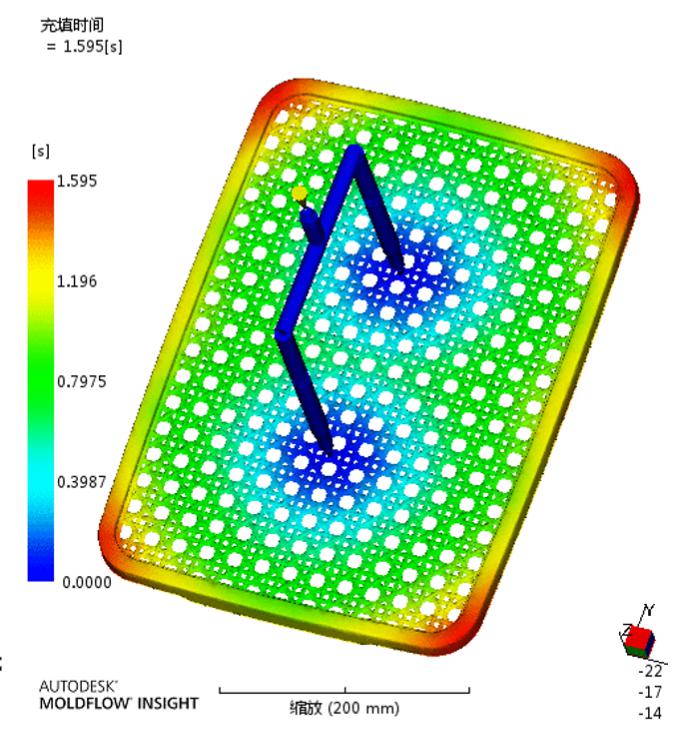

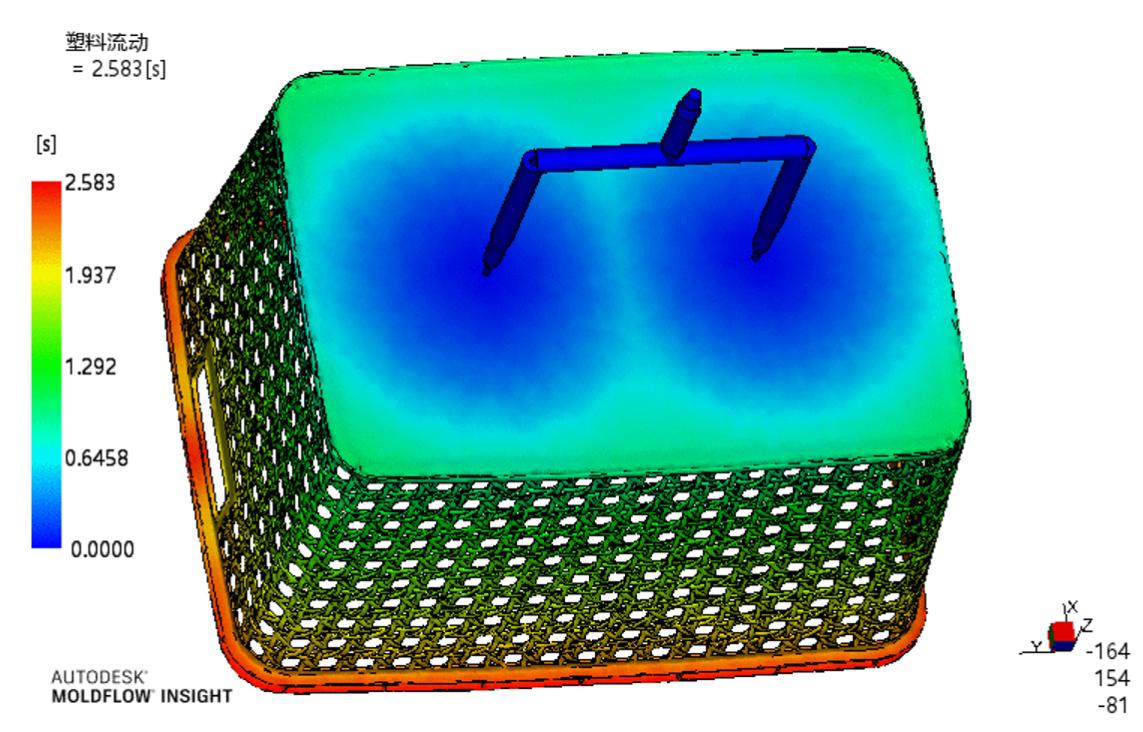

Mould Gate Design of Storage Basket

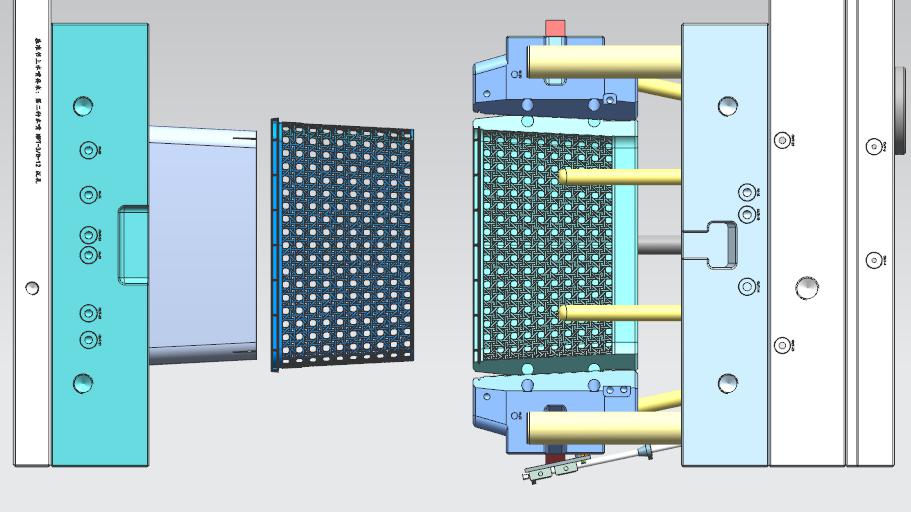

The storage basket adopts a multi-point needle valve gate, and the multi-point gate should achieve a balanced filling without trapping air. Combined with CAE analysis, gate location is determined. The choice of brand hot runner can make production stable and efficient.

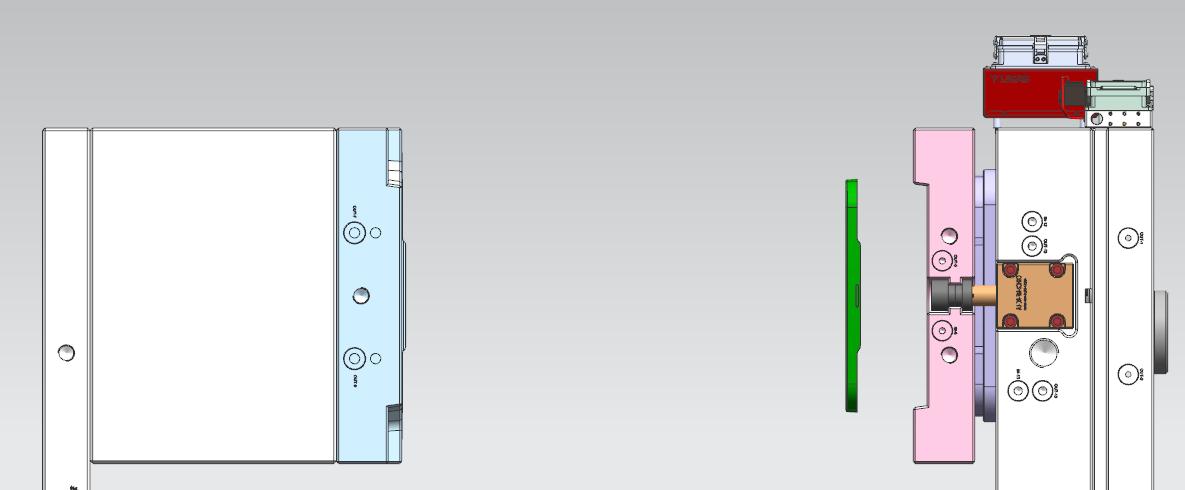

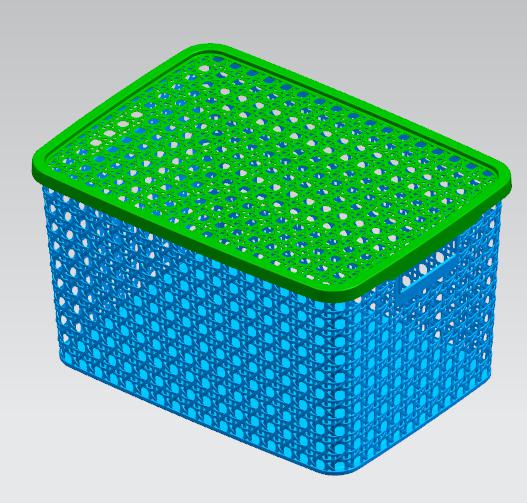

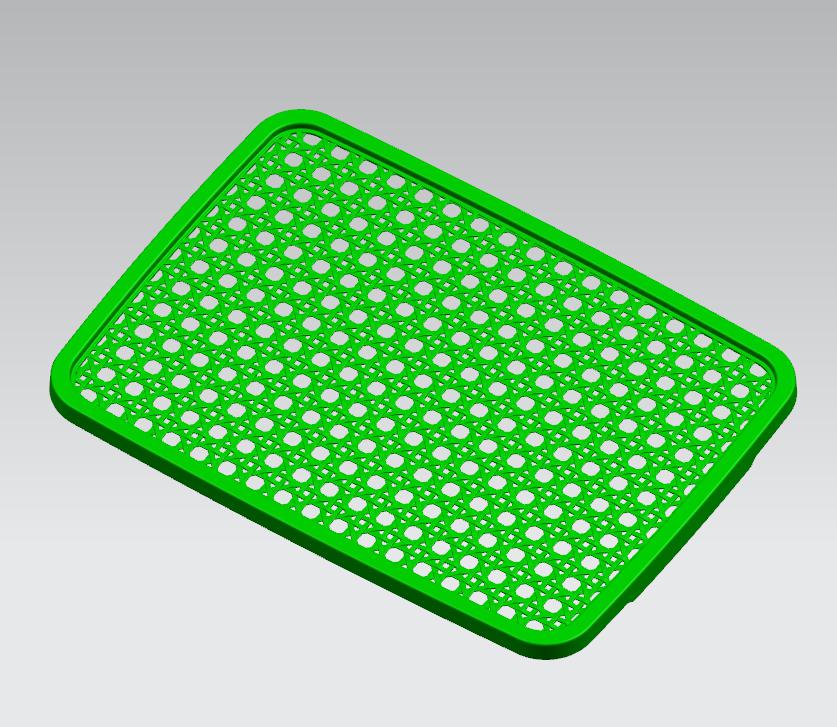

The storage basket can be produced by a double shot molding machine, so that the lid and the basket can be produced on a pair of molds at the same time, saving time and production costs.

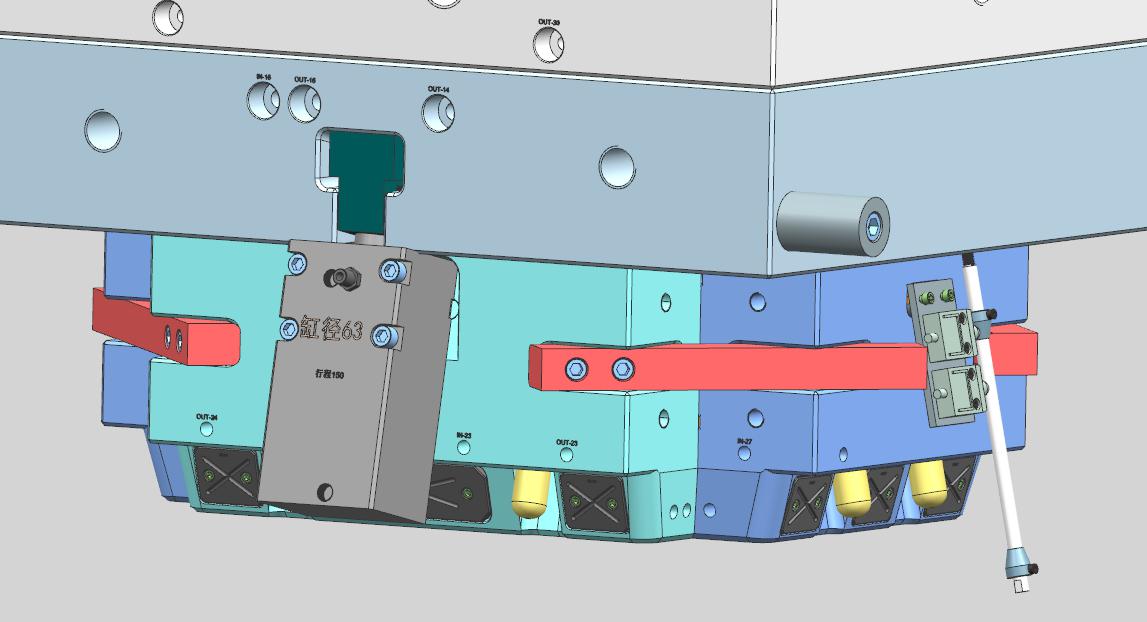

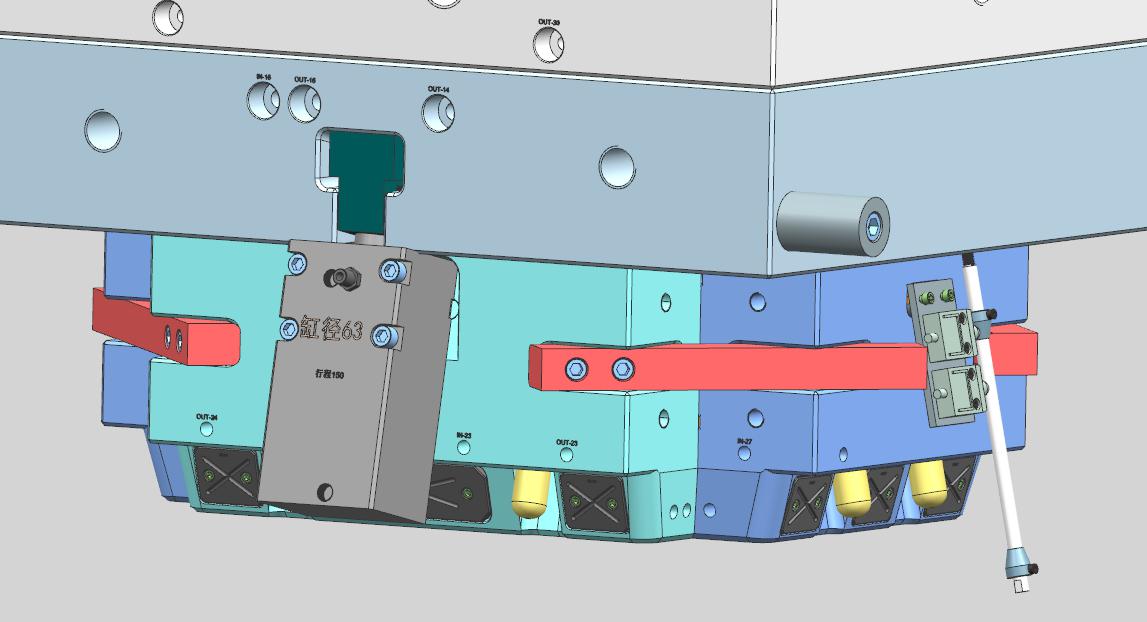

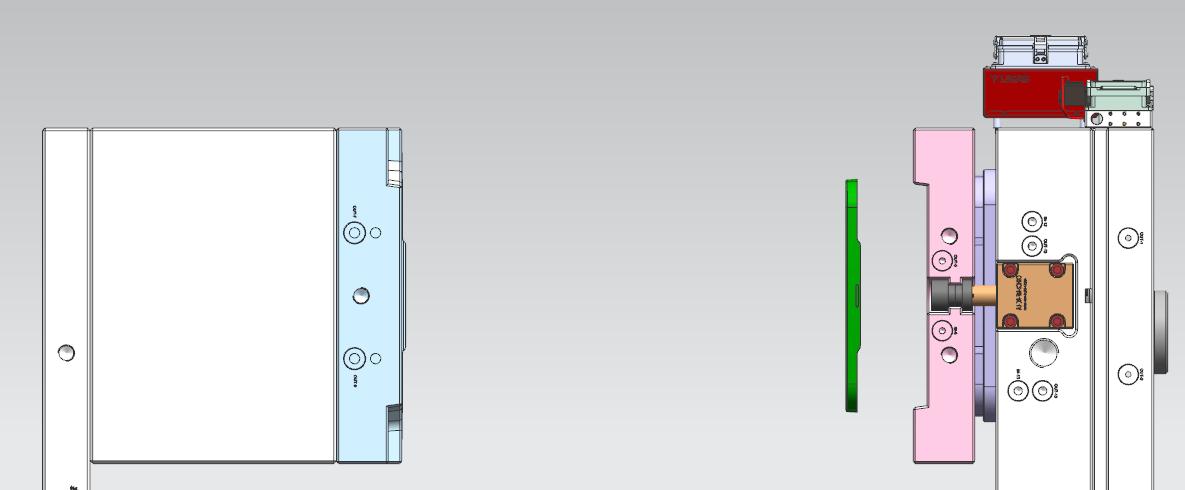

The Slider Core Pulling and Ejection System of the Storage Basket Mold

Most of the storage baskets are fixed mold four-slide core pulling, which can control the size of the mold and reduce the development cost compared with the moving mold slider core pulling. The action of the four sliders should be uniform, efficient and stable.

The cover is usually ejected by pushing the plate first, and then the manipulator is used to pick up the parts.

The basket usually adopts the fixed mold and four-slide core pulling, leaving the product on the movable mold, and then using the robot to pick up the parts.

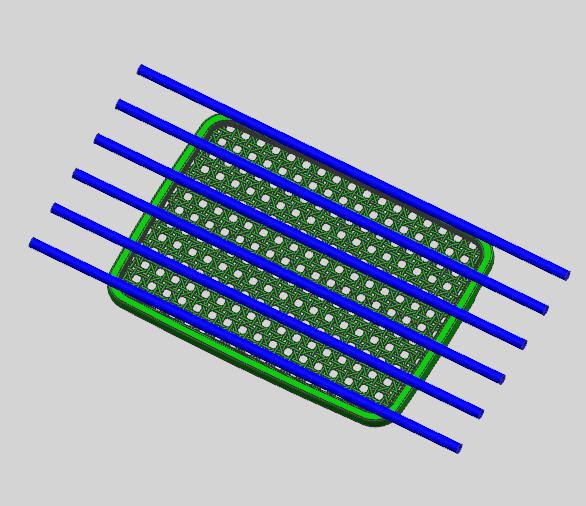

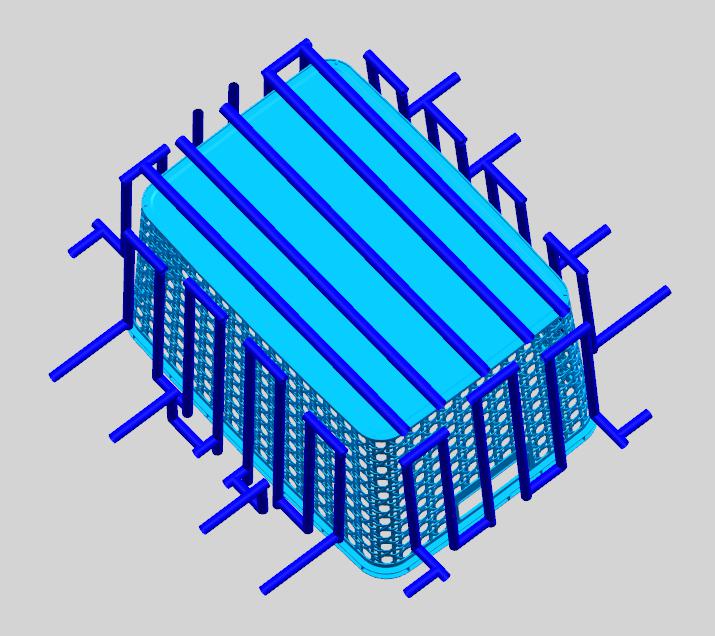

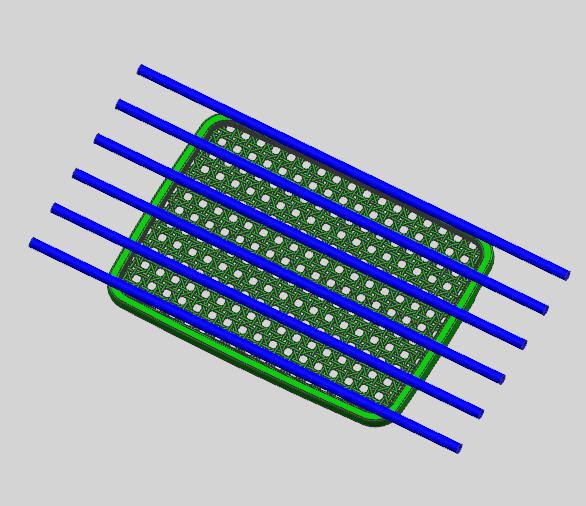

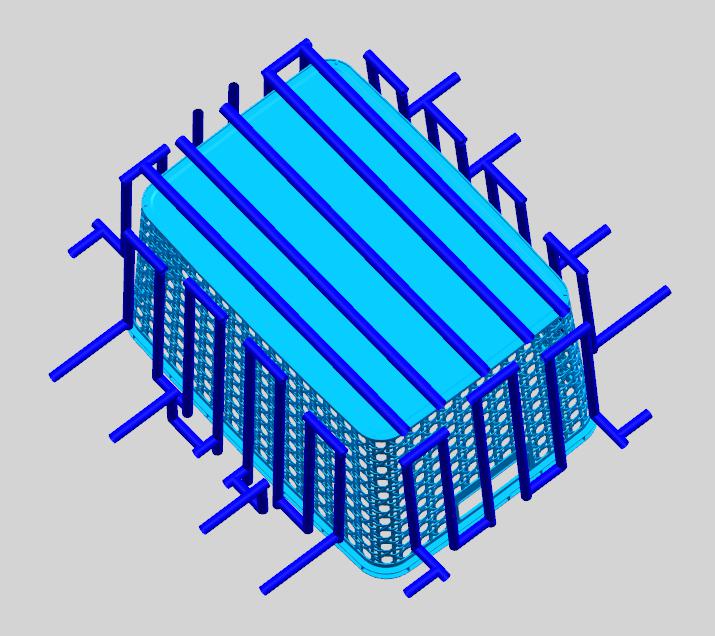

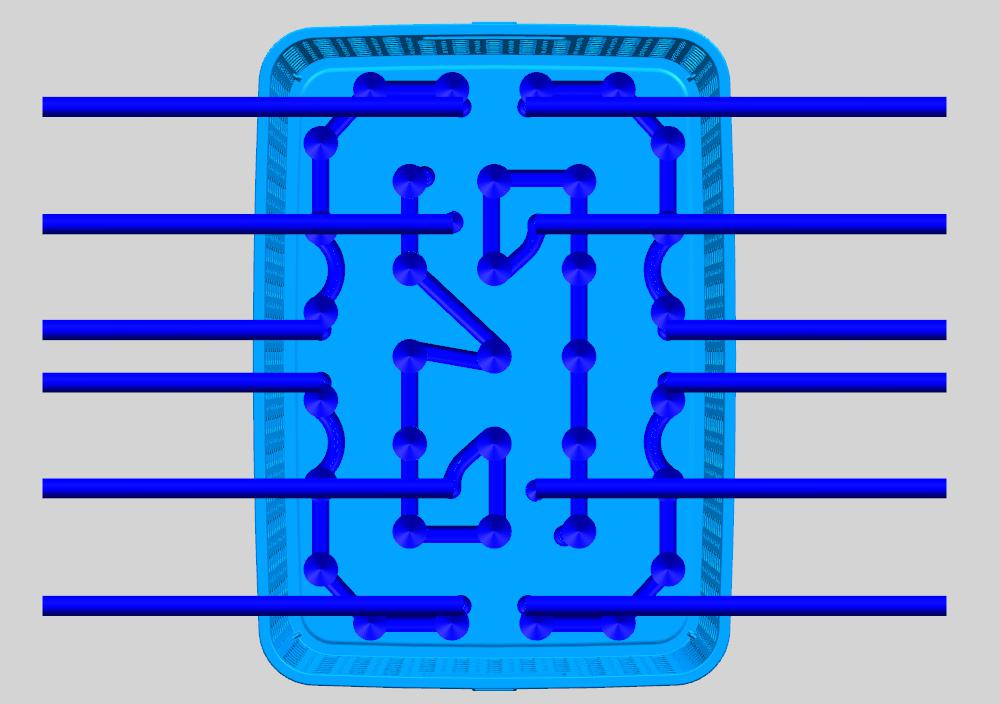

The Cooling Design of the Storage Basket Mold

The cooling of the storage basket mold is very important. Reasonable cooling can reduce the deformation of the product and shorten the injection molding cycle. The appropriate size of water channel diameter and uniform distance can ensure uniform cooling of the mold.